Precision and Control with the MC1200

The MC1200 delivers unmatched accuracy with double-sided board capability and repeatability of ±0.01 mm. Its adjustable vertical board-to-stencil separation and programmable print speed ensure clean, consistent results, even on complex fine-pitch boards. An optional dual-camera vision system provides X, Y, and theta alignment on an LCD screen, locking adjustments for the entire run. With one-touch operation, solder paste application and print stroking are performed automatically, while fully programmable squeegee movement and stencil separation speeds guarantee reliable, high-quality prints cycle after cycle.

Oversized Print Area for Maximum Flexibility

The MC1200 features an oversized print area of 1200 x 400 mm (47.3" x 15.75"), making it ideal for large-format applications such as LED panels, backplanes, and multi-board assemblies. For specialized requirements, custom print area sizes are also available, giving manufacturers the flexibility to adapt the printer to virtually any production need.

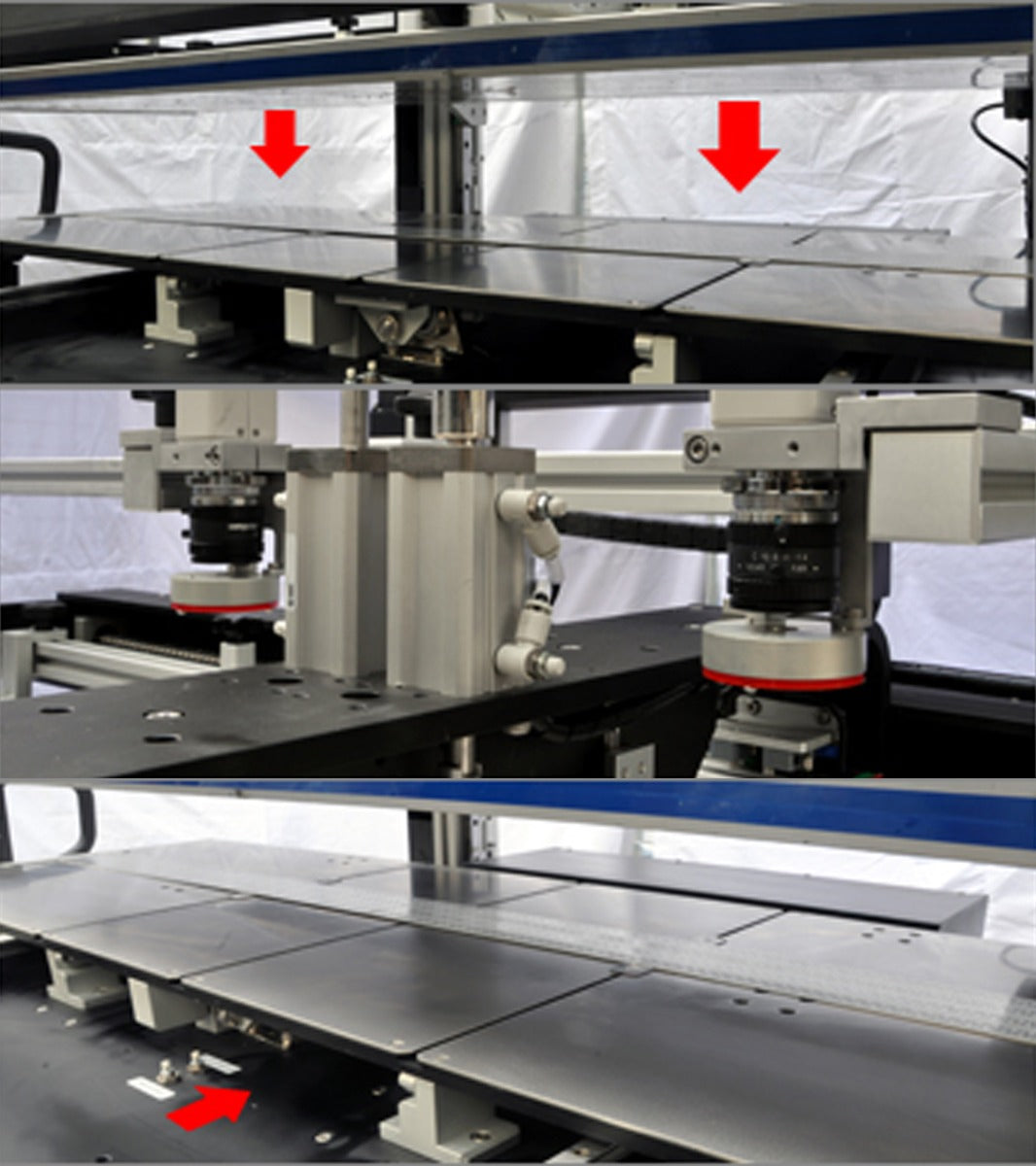

Printing with the MC1200 in Five Easy Steps

- Step 1:

- Place the PCB board on the slidable working table.

- Step 2:

- Press the IN button. The working table will move inside automatically.

- Step 3:

- Press the DOWN button and the stencil will automatically move downward.

- Step 4:

- Use the magnifying camera to adjust X, Y and theta alignment easily & precisely.

- Step 5:

- Press the START button to begin printing. The squeegee will then automatically begin to spread the solder paste.

| MC1200 Specifications | |

|---|---|

| PCB Max Size | 49" x 16" (1250 mm x 410 mm) |

| Stencil Frame Size (External) Min. | 350 mm x 350 mm |

| Stencil Frame Size (External) Max. | 1480 mm x 470 mm |

| Print Area | 1200 mm x 400 mm |

| Print Repeatability | 0.00039" (± 0.01 mm) |

| Underside Clearance | 1" (25 mm) |

| PCB Fixture | Screw clamps |

| Squeegee Type | Metal |

| Squeegee Pressure | Pneumatic Control |

| Print Type | Single and double sided printing |

| Cleaning Systems | N/A |

| X-Axis Adjustment | ± 0.51" (13 mm) |

| Y-Axis Adjustment | ± 0.51" (13 mm) |

| R Adjustment | ± 3.5° |

| Power Specs | 110/220V Selected at factory |

| Air Requirements | 80 psi 150L/min |

| Dimensions | 72" x 38" x 27" (1830 mm x 962 mm x 684 mm) |

| Weight | 357 lb (162 kg) |

Back

Back