Parallel Lift System for Superior Print Quality & Throughput

The AP Series stencil printers feature a parallel stencil-to-PCB lift system that ensures uniform separation across the entire print area, delivering consistently high print quality even on demanding applications. By maintaining precise, controlled movement during the separation process, the system minimizes paste smearing, reduces defects, and supports accurate printing of fine-pitch components and complex board designs. This reliability not only improves yield but also shortens rework cycles, resulting in higher throughput and greater overall efficiency for modern SMT production lines.

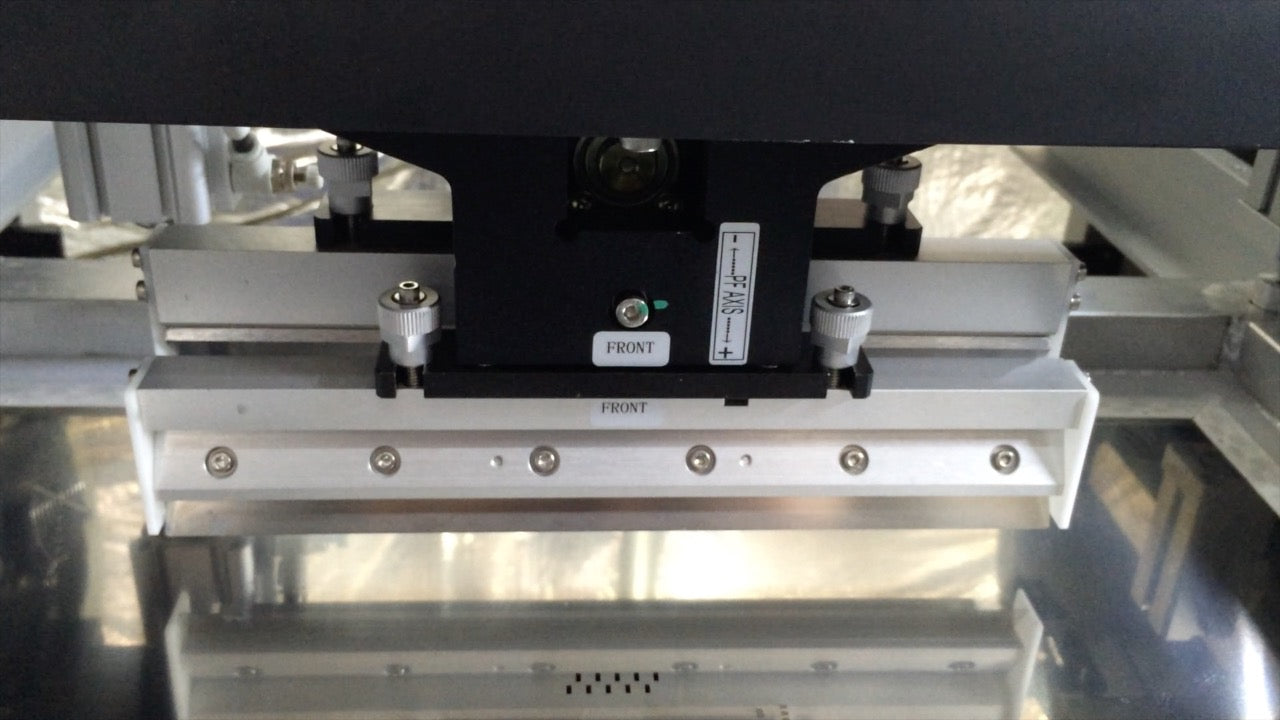

High-Accuracy Vision Alignment System

All AP series printers are equipped with an advanced camera system that automatically align the circuit board to the stencil before each print cycle, ensuring fast setup and consistent results. This high-precision design enables reliable printing of fine-pitch PCBs with a repeat accuracy of ±0.008 mm, making the AP series ideal for demanding SMT applications where precision and repeatability are critical.

Dual-Rack Squeegee Printing System

The AP660 features a dual-rack squeegee system driven by high-precision ball-screw actuators with programmable print speed for consistent and repeatable motion control. Uniform print pressure is precisely regulated, while self-leveling squeegees automatically conform to the stencil surface to ensure accurate registration on every print. This advanced dual-rack design also optimizes solder paste travel, minimizing waste and improving overall process efficiency for reliable, high-quality results.

Integrated Under-Stencil Cleaning System

The AP660 features an automatic wet/dry/vacuum under-stencil cleaning system that ensures consistent print quality and minimizes downtime. The programmable system allows flexible cleaning modes, including dry wiping, wet wiping with solvent, or wet wiping combined with vacuum suction to effectively remove solder paste and debris from stencil apertures, maintaining optimal performance throughout production. Manncorp recommends using Zestron Vigon SC200 for cleaning solution.

User-Friendly Programming and Control

The AP660's Windows-based platform streamlines setup, allowing the printer to be fully operational within minutes of installation. Key parameters—including print speed, stroke length, squeegee pressure, and more—are easily configured through an intuitive graphical user interface. During operation, the on-screen display provides real-time visibility of job details and process status, ensuring smooth workflow management, precise control, and maximum efficiency throughout every print cycle.

| AP660 Specifications | |

|---|---|

| PCB Min Size | 2" x 2" (50 mm x 50 mm) |

| PCB Max Size | 23.6" x 23.6" (600 mm x 600 mm) |

| Board Thickness | .015" to .197" (0.4 mm to 5 mm) |

| Stencil Frame Size (External) Min. | 26.7" x 11.8" (680 mm x 300 mm) |

| Stencil Frame Size (External) Max. | 35.43" x 35.43" (900 mm x 900 mm) |

| Flexible holder for single and double-sided PCBs | Yes |

| PCB Warpage | Max PCB 1% of diagonal line |

| Print Repeatability | 0.00031" (± 0.008 mm) |

| Print Accuracy | 0.00098" (± 0.025 mm) |

| Print Speed | 10-120 mm/s (Servo controlled) |

| Transport Cycle Time | 7s (Exclude printing & cleaning) |

| Transport Height | 35" ± 1.6" (900 mm ± 20 mm) |

| Transport Direction | Left-Right, Right-Left, Right-Right, Left-Left |

| Transport Speed | 60 in/s (1500 mm/s) Max |

| PCB Fixture | Screw clamping and vacuum |

| Support System | Transport rail & vacuum |

| Interface | SMEMA |

| Squeegee Type | Metal/Plastic (45°/55°/60°) Fixed |

| Squeegee Pressure | 0-33 lbs (0-15kg) Servo Controlled |

| Print Type | Single and double sided printing |

| Cleaning Systems | Dry/Wet/Vacuum - Integrated |

| Camera/FOV | CCD/FOV 5x7 mm |

| Fiducial Type | Circular/Square/Triangle/Rectangle |

| Fiducial Size | 0.019" to 0.12" (0.5 mm to 3 mm) |

| X Adjustment | ± 0.39" (10 mm) |

| Y Adjustment | ± 0.39" (10 mm) |

| R Adjustment | ± 2° |

| Environmental Monitoring | None |

| Operating System | Industrial PC with Windows 10 |

| Power Specs | 230V, 50/60 Hz |

| Air Requirements | 75 psi |

| Dimensions | 58" x 59.2" x 61" (1470 mm x 1506 mm x 1550 mm) |

| Weight | 1850 lbs (840 kg) |

| Option | |

| 2D Inspection | Yes |

Back

Back