Mobile-Ready

The new KIC K2 Profiler features the latest technology in thermal profiling, including an Android app, allowing you to analyze profiles right on your phone or tablet. A convenient sharing function for selected profile data allows you to share with other users over WiFi or Bluetooth.

Slim, Durable Design

The K2's slim profile—just 23 mm (0.9") thick when inserted in its shield—is designed to fit through the tight heating chambers common to lead-free production. Manufactured out of durable hardware, it can withstand—and provide accurate measurements in—even the toughest production environments.

Simple Yet Powerful

To ensure consistent starting points and repeatable profiles, the K2 has an automatic-start function that's triggered when temperatures are below a set point. Quality and productivity related parameters, such as PWI (process window index) level, minimum and maximum allowable conveyor speed, and maximum peak temperature, are fully controllable by your engineer. Profiling can then be run by operators, techs, and engineers.

Optimize a Profile in Seconds

The included KIC profiler oven optimization software takes just seconds to choose the ideal setup for any product by searching all possible combinations of zone temperatures and conveyor speeds. The aim of the software is to find the profile that comes closest to the center of the process window while maximizing conveyor speed and minimizing power consumption.

| KIC K2 Specifications | |

|---|---|

| Dimensions (L x W x H) | 7-channel 206 x 60 x 17 mm (8.1" x 2.4" x 0.7") With shield: 302 x 75 x 23 mm (11.9" x 3" x 0.9") 9-channel 206 x 75 x 17 mm (8.1" x 3" x 0.7") With shield: 312 x 90 x 23 mm (12.3" x 3.5" x 0.9") |

| Accuracy | ± 0.5°C |

| Resolution | 0.1°C |

| Internal Operating Temp. | 0°C to 85°C |

| Sample Rate | 0.1 to 10 readings/sec |

| Data Points | 224,640 |

| PC Connection | USB 2.0 (Std-A/Mini-B) |

| Power Requirements | 3 AAA batteries |

| Thermocouple Capacity | Type K, standard (7 or 9, depending on model) |

| Thermocouple Temperature Range | -150°C to 1050°C |

| Thermal Shield | Cool Touch Stainless Steel 7 or 9 channel |

| Mobile App Requirements | Authorized Android Device WiFi or Bluetooth for data transfer |

| Computer Configuration Minimum System Requirements | Dual Core / 1 GHz processor PC w/2 GB RAM 2 GB available storage Video 1024 x 768 resolution, 16-bit 1 available USB port for data download 1 available USB port for software key |

KIC 'K2' Key Features

- Mobile device compatible: Conveniently view and share profiles to Android mobile devices

- Cable-free data transfer: Mobile app is WiFi and Bluetooth compatible

- Latest technology in thermal profiling

- Slim profile: Fits through tight heating chambers

- Simplifies oven setup: KIC's optimization software selects the best oven setup for each new product in seconds

- Reduces profiling to a single number: The PWI (process window index) makes it easy for operators, techs, and engineers to see at a glance how close the profile comes to spec.

- User-selectable setup criteria

- Immediate profile analysis: Objective and personnel-independent profile analysis gives you information you can bank on.

- Priced for the mid-range market

- 30-day money back guarantee

AUTOMATICALLY SET UP THE BEST RECIPE FOR ANY PRODUCT IN ANY REFLOW OVEN

The KIC Navigator software option for the K2 makes it possible to optimize oven setup even for strict process requirements, ensuring maximum product throughput, better equipment utilization and more efficient staff allocation.

KEY FEATURES

- Finds the Best Possible Profile in Less Than 60 Seconds

- Enable Deep-In-Spec Profile

- Determines Single Best Oven Recipe for Every Product

- Maximize Product Throughput

HOW IT WORKS

KIC's powerful Navigator™ software is a system that automatically determines the single best oven recipe for every product. Once the initial profile is run, the Navigator evaluates billions of combinations of conveyor speeds and setpoint temperatures in less than a minute, so operators no longer need to set search parameters.

You give the Navigator your profile specs and the Navigator presents the process set up that will produce a profile centered in the process window, with the lowest Process Window Index™ (PWI). With the Navigator, an operator with limited process knowledge can find the optimal profile every time.

Whether it takes you two runs to set up a simple profile, or 5 runs for a difficult one, why spend the time? The Navigator finds the best possible profile in less than 60 seconds. This means more efficient use of the engineering resources, increased line uptime, and improved line uptime - which all mean an improved bottom line.

Without the power of the Navigator, solder reflow oven setpoint changes are typically made in 5°C increments. Research made possible by the Process Window Index shows that setting up the oven in smaller increments offers significantly improved process performance. Extensive testing revealed substantial benefits in setting up profiles in 1°C increments. Slight setpoint changes in the soak and reflow zones produced more robust profiles that reduced temperatures at hot spots on the board and provided more even heating across the assembly. Precision profiling also makes developing tight-spec lead-free profiles as quick and easy as any other profile with the Navigator.

COMPUTER REQUIREMENTS

Minimum System Requirements

- Dual Core / 1 GHz Processor with 2 GB RAM

- 2 GB available storage

- Video 1024 x 768 resolution / 16-bit

- 1 available USB port (for software key)

- Microsoft® Windows® XP 32b SP3 and later

THE PROCESS WINDOW INDEX™ (PWI)—PROFILING REDUCED TO A SINGLE NUMBER

The PWI measures the profile's fit to the process window in a mathematical and objective manner by using a single number. This aids in optimizing the process by comparing and ranking alternative profiles in terms of their fit to the available process window. The lower the PWI, the more efficient and stable the process!

ABOUT THE PROCESS WINDOW INDEX (PWI)

There are statistically valid methods for quantifying most EMS processes, such as pick and place and screen printer performance. However, until now there has been no widely accepted method for measuring, analyzing and comparing the performance of thermal profiles, and no means of ranking their suitability for reflow of newly introduced boards. The Process Window Index (PWI™), developed exclusively by KIC, is a simple way of statistically measuring and ranking how good any given profile is relative to critical process limits.

PWI ranks every thermal profile by where it "fits" within the user defined process window. Optimum performance is achieved at the center of this window, and is designated as 0%. The opposite or extreme edge is defined as 99%, A PWI of 99% indicates that the profile will process product within spec, but is running at the very edge of suitability, and of course, any boards processed with a PWI above 99% risk certain rejection. So for example, if the highest recommended temperature is 250° C and the lowest is 235° C, the zero point or optimal PWI would be midway between these extremes, or 242° C. The PWI reveals exactly where a given profile numerically ranks within the process window, which is a clear designation of how viable that profile is. Although slight fluctuations or deviations are normal in the reflow process, it's a certainty that the lower the PWI, the better the profile. It's as simple as that!

THE BENEFITS AND ADVANTAGES OF PWI RANKING

Greatly Simplify & Speed The Profiling Process. All profile statistics are reduced to a single number - the PWI - that anyone can understand. When using advanced KIC profiling tool, such as Navigator, the PWI aids in speeding up the whole profiling process by making it easier to understand.

Instill Confidence in Thermal Process Capability. he PWI is not just a single statistic. It reflects the performance of the entire profile and thus aids in generating the best profile a process can achieve, opening the door to precise profile control.

Profiles Can Be Easily Compared .Comparisons can now be made quickly -- between individual lines on the shop floor, between processes at multiple plants and between processes using dissimilar equipment. With PWI, profile comparison is no longer subjective, since it ascertains that the best profile is being used.

Attain Improved Quality Control. is ideal for use with SPC and other QC monitoring platforms. It is a significant step towards zero-defect production.

Lower Production & Equipment Costs. Immediate savings can be realized in each of these areas: staff training; operator errors; production monitoring and data collection; process troubleshooting, and pre-purchase equipment evaluation.

CALCULATING THE PWI

The Process Window Index for a complete set of profile statistics is calculated as the worst case (highest number) in the set of statistics. For example: if you run a profile with three thermocouples, and four profile statistics are logged for each thermocouple, then there will be a set of twelve statistics for that profile. The PWI will be the worst case (highest number expressed as a percentage) in that set of profile statistics.

The Process Window Index is calculated using a formula that includes all statistics for all thermocouples. The formula for the PWI is calculated as follows:

i=1 to N (number of thermocouples)

j=1 to M (number of statistics per thermocouple)

measured_value[i,j]=the [i,j]th statistic's value

average_limits[i,j]=the average of the [i,j]th statistic's high and low limits

range[i,j]=the [i,j]th statistic's high limit minus the low limit

Thus, the PWI is the worst case profile statistic (Maximum, or highest percentage of the process window used), and all other values are less.

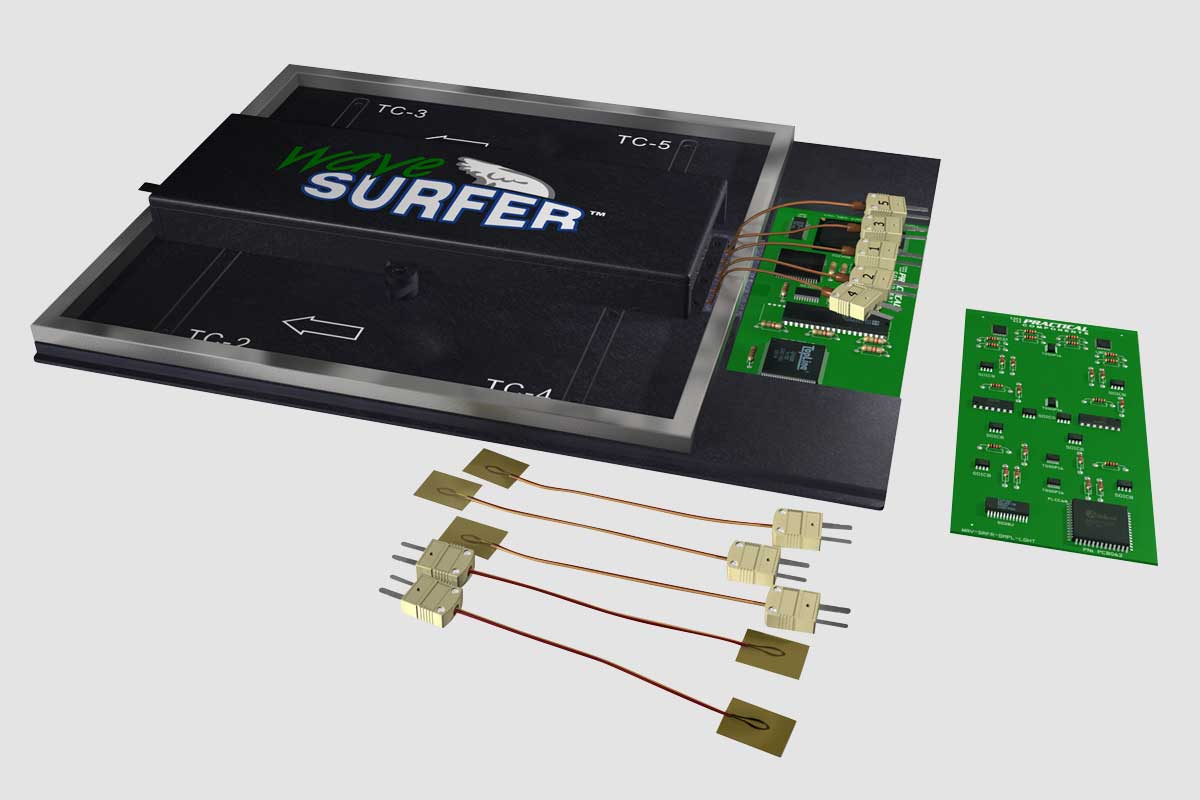

Wave Surfer - Profiling Fixture for Wave Solder Machines

Verify wave solder process and fine-tune the machine for optimum performance.

Profiler Carrier for Edge Conveyor Reflow Ovens (no mesh belt)

Facilitates reflow profiling in ovens with edge conveyors -- with and without center board support. Also ideal for low-clearance ovens and those with extra-wide conveyor rails up to 379mm (14.92"). Minimum Dimensions (L x W X H): 400mm x 111mm x 17.5mm (15.75" x 4.37" x 0.69"). Maximum Dimensions: 400mm x 379mm x 17.5mm (13.75" x 14.92" x 0.69").

Maximum endurance in minutes at specified temperature.

| SHIELD | 150°C | 200°C | 250°C | 300°C | 350°C |

|---|---|---|---|---|---|

| 7-channel profiler endurance in minutes | 17.5 | 12.0 | 9.0 | 7.7 | 6.5 |

| 9-channel profiler endurance in minutes | 18.1 | 13.1 | 10.1 | 8.4 | 6.7 |

KIC 'K2' Kit Contents

- Profile setter

- Thermal shield

- Software CD

- Software protection dongle

- USB cable (A male/mini-B)

- AAA batteries (6)

- Scissors

- Carrying case

- Thermocouples

- Electronic user manual

- Electronic hardware guide

- Gloves

- Getting started guide

- Calibration certificate

Back

Back