Simple Set-Up

The AP435 makes job set-up fast and easy; simply input the stencil size, insert the stencil into the frame clamp, and the system software will handle the rest. Be ready for the next production assignment in a matter of seconds.

Total Programmability

Our Windows-based equipment is easy to program, allowing your printer to be up and running quickly after install. All parameters, including print speed (programmable from 10 to 120 mm/s), stroke length, squeegee pressure, and more, are fully programmable via the graphical user interface. During operation, all details of the current job, including processing status, will be displayed on-screen for easy viewing.

High Throughput Rate

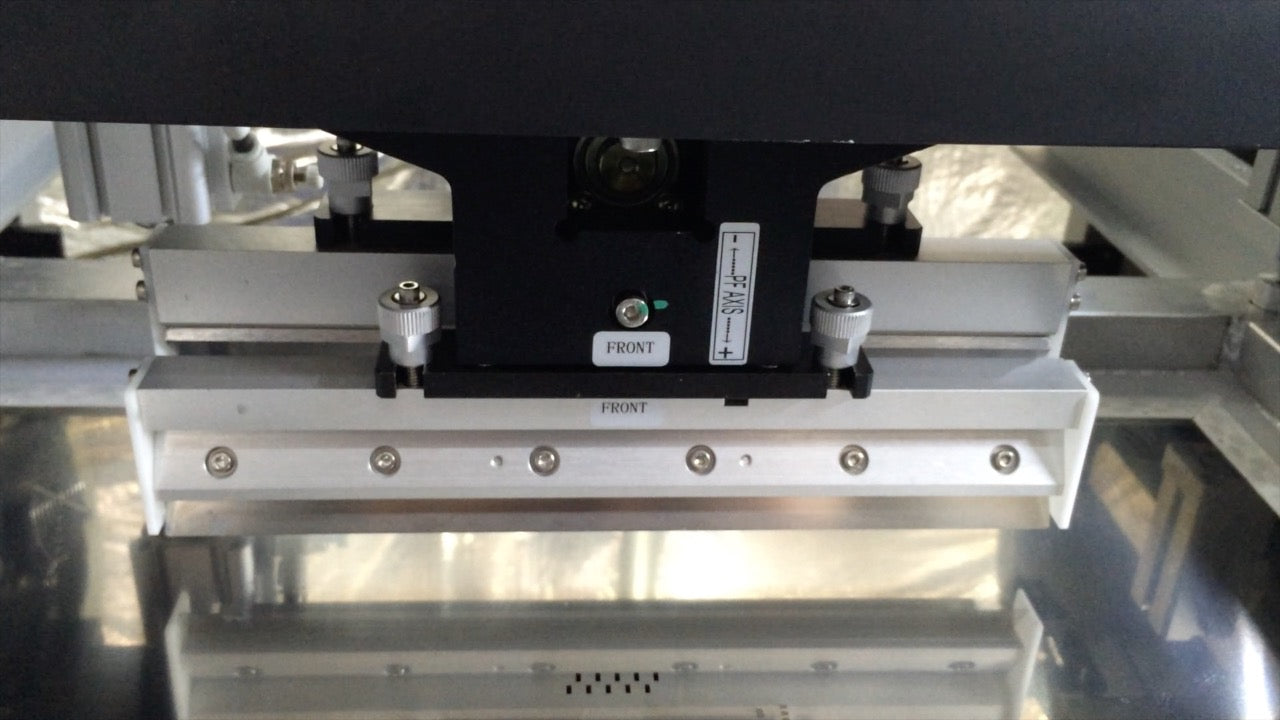

The machine’s dual-squeegee system is controlled by high-precision ball-screw drives with programmable transport speeds. Print pressure is uniformly and accurately controlled. Self-leveling squeegees automatically adjust to the stencil surface to ensure perfect registration on every print.

SMEMA Integration-Capable

The efficient single-stage PCB transport system is SMEMA-compatible for interface connectivity with the other production equipment in your assembly line.

Under-Stencil Wiping

Automatic wet/dry/vacuum under-stencil cleaning is integrated into the AP435. The system can be programmed to clean the stencil using any combination of dry wipe, wipe with solvent (“wet wiping"), or wipe combined with a vacuum to draw material out from the apertures. Manncorp recommends using Zestron Vigon SC200 for cleaning solution.

| AP435 Specifications | |

|---|---|

| Printing Speed | 6 to 200 mm/s |

| Transport Cycle Time | 7s (excluding printing and cleaning) |

| Vision Alignment System | Automatic |

| Stencil Frame Size (External) | 470 x 370 mm to 736 x 736 mm (18.5" x 14.56" to 29" x 29") |

| Board Size | Min: 50 x 50 mm Max: 400 x 340 mm |

| Board Thickness | 0.4 to 3 mm |

| Automatic Paste Dispense | Optional |

| Automatic Glue Dispense | Optional |

| Squeegee Blade Type | Metal |

| Squeegee Pressure | 0 - 15 kg (Motorized Control) |

| X,Y,R Adjustment | X and Y ±10mm, R ±2° |

| Registration Repeatability | ±.01 mm |

| PCB Fixation | Side Clamp, Magnetic Support Pins, Vacuum Tooling |

| CCD FOV | 7 x 9 mm |

| Vision Fiducial | Standard Fiducial or Odd Shape .5 to 3 mm |

| Environmental Monitoring | Temperature and Humidity Real Time Monitoring |

| Power Requirements | 220VAC 50-60Hz |

| Air Requirements | 75 Psi 4.5 - 6 kgf / cm2 |

| Dimensions | 1220 x 1373 x 1450mm (48 x 54 x 57”) |

| Weight | 1000 kg (2200 Lbs) |

Back

Back