High-Speed, High-Efficiency Design

The 6-head MCLEDV6 delivers exceptional throughput with a high-speed linear drive gantry that performs simultaneous multi-part pick-up, achieving placement rates of up to 30,000 LEDs per hour (per IPC-9850). Its true fly-over alignment system, featuring an upward-looking camera positioned between the feeder base and the PCB, accurately aligns components while the placement head is in motion. This maximizes efficiency without sacrificing precision. Built-in software further enhances performance by optimizing feeder locations before placement begins, minimizing head travel and reducing tool changeovers.

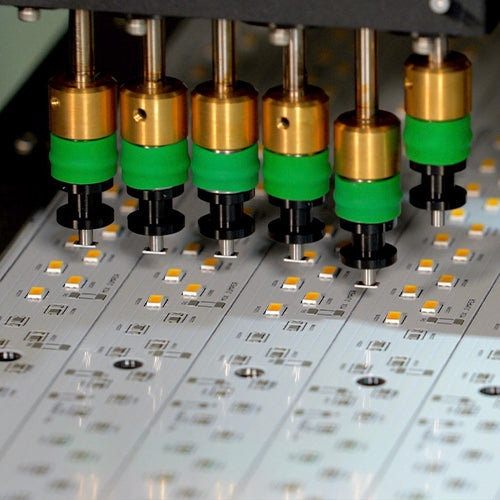

Purpose-Built for LED Assembly

The MCLEDV6 is engineered specifically for LED production, not adapted from general-purpose pick and place machines, ensuring optimal performance for LED board assembly. It supports a wide range of LED components, from 0402 packages to larger 20 mm x 18 mm LEDs, including both standard and irregular shapes, as well as small connectors and resistors.

Each of the six placement heads is equipped with positive air pressure to reliably release adhesive-prone LED components. To further ensure smooth operation, non-stick, Teflon®-coated nozzles are available, including custom designs tailored to specific LED geometries. Specialized nozzles for rounded LEDs are designed to avoid contact with the optical lens during pick-up, preserving the integrity and performance of sensitive components.

Versatile Solutions for All LED Lighting Products

The MCLEDV6 is designed to handle a wide range of LED lighting applications, including flexible PCB strips, circular bulb boards, and irregularly shaped panels, all with speed, accuracy, and reliability. Every model assembles the full length of the board in a single pass, maximizing throughput and production efficiency. The MCLEDV6 comes standard with a worktable and magnetic board fixture but can also be configured at the time of purchase with a SMEMA-compatible inline conveyor for fully automated operation.

Streamlined Software for Smarter LED Production

The MCLEDV6 comes equipped with powerful, easy-to-use software designed to simplify and accelerate LED production. Programming is fast and intuitive using a simple three-point selection of LEDs, the software automatically calculates all remaining LED positions across the board. The included UCAD® universal CAD import and conversion utility further streamlines setup, while the feeder arrangement optimizer minimizes head travel and tool changes for maximum throughput. Real-time production monitoring provides a virtual view of the assembly process, showing placement rates, cycle times, and production counts at a glance. Full traceability of all production data ensures reliable performance and accountability from start to finish.

Continuous Production Without Downtime

The MCLEDV6 is engineered for nonstop, high-efficiency production. When a feeder runs out of components, the system can automatically switch to a backup feeder loaded with the same part, allowing operators to replenish empty feeders without halting the production process. Up to 16 special servo-driven feeders can be used with the MCLEDV6, each equipped with brushless motors to ensure extended service life even in 24/7 production environments. These feeders also support tape splicing, enabling seamless transitions from depleted reels to new ones and minimizing interruptions for maximum throughput.

| Placement Specifications | ||

|---|---|---|

| Number of Placement Heads | 6 | |

| Placement Rate (IPC-9850) | N/A | |

| Placement Rate (Max.) | 30,000 CPH | |

| Placement/Positioning Accuracy | ±0.05 mm | |

| Feeder Capacity (8mm/12mm) | 16 | |

| IC Tray Capacity (Waffle Trays) | 0 | |

| Placement Area w/o Waffle Tray with No Conveyor | 600mm: 600 x 300 mm 1200mm: 1200 x 300 mm |

|

| Placement Area with Waffle Tray with No Conveyor | N/A | |

| Placement Area w/o Waffle Tray with Conveyor | 600mm: 600 x 300 mm 1200mm: 1200 x 300 mm |

|

| Placement Area with Waffle Tray with Conveyor | N/A | |

| BGA/CSP Placement Capability | No | |

| Alignment Method | Cognex Vision on the Fly | |

| Nozzle Change Capacity | 18 | |

| Integral Vacuum | Yes | |

| Min. Component Size | 0402 | |

| Max. Component (Using head camera) | 18 x 20 mm | |

| Max. Component (Using bottom camera) | N/A | |

| Max. Component Lead Pitch | N/A | |

| Mechanical Specifications | ||

| X/Y Axis Resolution | 0.02 mm | |

| X/Y Drive Mechanism | Ballscrew X Axis Linear Motor Y Axis |

|

| X/Y Drive Motor | AC Servo | |

| X/Y Encoding | Rotary Encoder - X Linear Encoder - Y |

|

| X/Y Resolution | 0.02 mm | |

| X/Y Repeatability | ±0.01 mm | |

| Z Drive Motor | AC Servo | |

| Z Encoding | Rotary | |

| Z Axis Resolution | 0.02 mm | |

| R Drive Motor | AC Servo | |

| R Encoding | Rotary | |

| R Resolution | 0.045° | |

| Rotation 0-360° | 0.09°/step | |

| PCB Specifications | ||

| PCB Loading | Inline | |

| Fiducial Recognition/Coordinate Correction | Yes | |

| Bad Mark Detection | Yes | |

| Programming | ||

| Operating System | Industrial PC with Windows® 11 | |

| PC, Keyboard, Mouse | Yes | |

| Monitor | Flat LCD | |

| Direct Input | N/A | |

| Teaching Camera | Yes | |

| CAD Download | Yes | |

| Step & Repeat for Matrix Boards | Yes | |

| Bar Code Reader for Feeders & Packaging | Option | |

| MIS & Optimization Functions | Yes | |

| Off-line Programming | Option | |

| Dispenser Specifications | ||

| Dispensing Head | N/A | |

| Dispense Method | N/A | |

| Dot Size | N/A | |

| Placement Speed | N/A | |

| Power Sources | ||

| Power Supply | 230 VAC | |

| Power | 3700W | |

| Air Supply | 75psi, 150L/min | |

| Physical Specifications | ||

| Machine Dimensions (Approx. L x W x H) | 600 mm Length Board: 1230 mm L x 1130 mm W x 1491 mm H (48" x 44" x 58.7") |

1200 mm Length Board: 2630 mm L x 1130 mm W x 1491 mm H (103.5" x 44" x 58.7") |

| Weight | 600 mm: 770kg 1200 mm: 850kg |

|

| Service and Support | ||

| Remote Diagnostics | Yes - TeamViewer via Internet | |

| Warranty (Major Components) | 1 Year - Extended Available | |

Back

Back