Dual-Vision System for Maximum Component Versatility

The MC400 is equipped with a dual-vision system that enables precise placement across the widest range of SMD components from ultra-miniature 01005s to large devices up to 100 x 150 mm. Smaller components are aligned using the high-speed, head-mounted Cognex® on-the-fly vision system, delivering non-contact precision for CSPs, µBGAs, and other fine-pitch parts. For larger components, the base-mounted upward-looking camera provides accurate alignment and placement. This intelligent vision combination ensures unmatched versatility, speed, and accuracy across all component types.

User-Friendly, Field-Tested Software Built for Efficiency

The MC400 operates on the same robust, Windows®-based software platform used across the enter MC Series—refined through over a decade of real-world customer feedback. Designed for reliability and ease of use, it supports programming via CAD import and conversion, manual teaching, or direct entry. After importing CAD data, users follow intuitive setup steps to configure PCB layout, assign feeders, and define component placements, streamlining job setup. Component data integrates seamlessly with the Smart Feeder system, simplifying inventory control and production preparation. A built-in virtual PCB simulator visually confirms the assembly for fast, accurate verification before the first board is placed.

During production, the interface provides real-time monitoring of pick camera images, production speed, run time, task lists, and PCB status. The system tracks component placement in real time, allowing seamless recovery after interruptions by resuming exactly where it left off.

Operators can adjust feeder settings, placement data, or machine speed on the fly—without leaving the production window—ensuring uninterrupted operation, minimized downtime, and maximum productivity.

Move Quickly from Prototyping to Production

The MC400 is built to bridge the gap between prototyping and production, offering placement rates of up to 2,500 CPH (IPC-9850), support for up to 64 feeder slots, and high-precision components such as X-Y linear encoders and Smart Feeders. Its system software automatically optimizes feeder locations and placement sequences to maximize throughput, allowing users to scale efficiently without reprogramming or retraining. Because the MC400 shares the same software platform, feeders, and technology as all other MC-Series machines, upgrading to a larger model or expanding with additional systems is seamless—programs are fully transferable, feeders are interchangeable, and operators can work within a familiar interface.

Set Up to Suit Your Needs

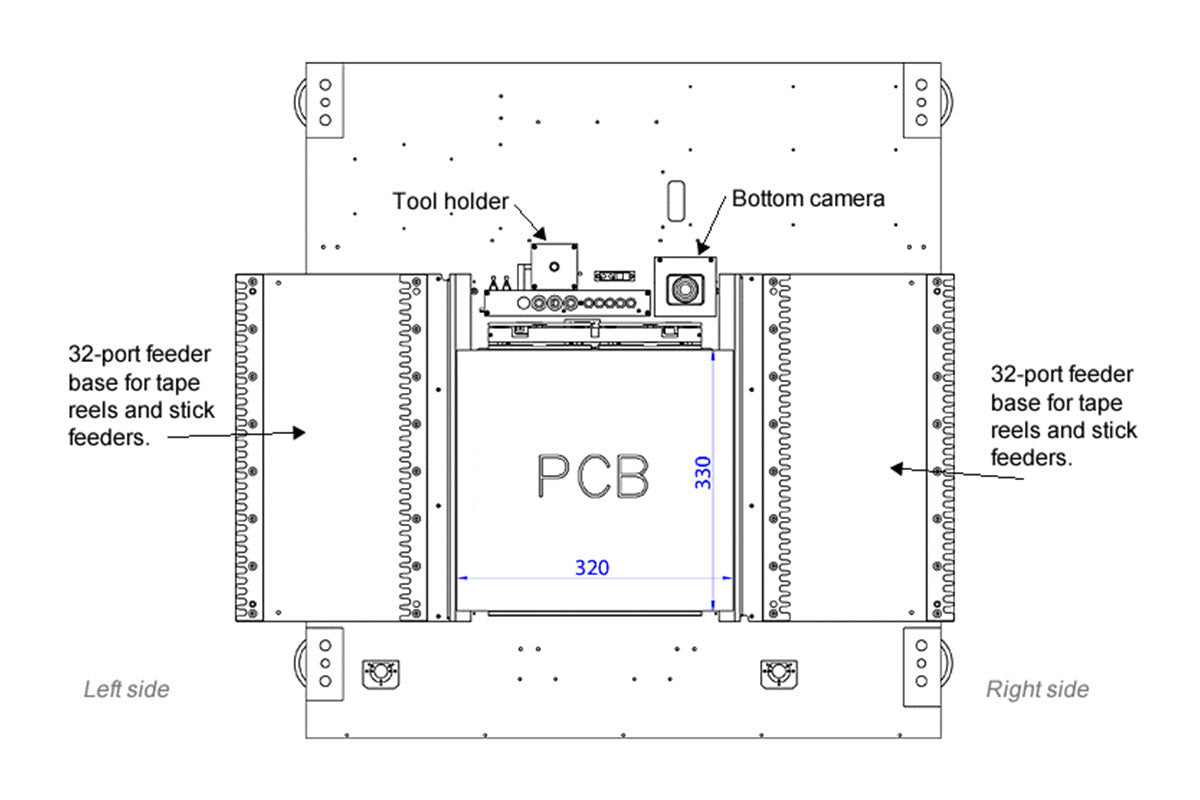

The MC400 offers unmatched flexibility with various different machine configurations to match a wide range of production requirements. Whether using waffle trays, cut strip holders, or reel feeders, the system can be tailored to your workflow. It's especially cost-effective for prototyping and small-batch jobs, as it supports the use of only the quantities of components needed, avoiding the expense of full reels. Cut strip tape holders are available for 8 mm, 12 mm, 16 mm, and 24 mm tapes, and the machine provides 64 slots for tape and stick feeders. Additionally, its Semi-Automatic mode enables pickup, orientation, and placement of loose components from bulk trays, giving you full control over how you handle a variety of parts.

| Placement Specifications | |

|---|---|

| Number of Placement Heads | 1 |

| Placement Rate (IPC-9850) | 2,500 CPH |

| Placement Rate (Max.) | 3,000 CPH |

| Placement/Positioning Accuracy | ±0.05 mm |

| Feeder Capacity (8mm/12mm) | 64 |

| IC Tray Capacity (Waffle Trays) | 3 |

| Placement Area w/o Waffle Tray with No Conveyor | 320 x 415 mm |

| Placement Area with Waffle Tray with No Conveyor | 320 x 270 mm |

| Placement Area w/o Waffle Tray with Conveyor | N/A |

| Placement Area with Waffle Tray with Conveyor | N/A |

| BGA/CSP Placement Capability | Yes |

| Alignment Method | Cognex Vision on the Fly |

| Nozzle Change Capacity | 7 |

| Integral Vacuum | Yes |

| Min. Component Size | 01005 |

| Max. Component (Using head camera) | 16 x 14 mm |

| Max. Component (Using bottom camera) | 150 x 100 mm |

| Max. Component Lead Pitch | 0.3 mm |

| Mechanical Specifications | |

| X/Y Axis Resolution | 0.005 mm |

| X/Y Drive Mechanism | Belt |

| X/Y Drive Motor | AC Servo |

| X/Y Encoding | High Precision Rotary Encoder |

| X/Y Resolution | 0.005 mm |

| X/Y Repeatability | ±0.01 mm |

| Z Drive Motor | DC Servo |

| Z Encoding | Rotary |

| Z Axis Resolution | 0.01 mm |

| R Drive Motor | DC Servo |

| R Encoding | Rotary |

| R Resolution | 0.045° |

| Rotation 0-360° | 0.09°/step |

| PCB Specifications | |

| PCB Loading | Manual Batch Mode |

| Fiducial Recognition/Coordinate Correction | Yes |

| Bad Mark Detection | Yes |

| Programming | |

| Operating System | Industrial PC with Windows® 11 |

| PC, Keyboard, Mouse | Yes |

| Monitor | Flat LCD |

| Direct Input | Yes |

| Teaching Camera | Yes |

| CAD Download | Yes |

| Step & Repeat for Matrix Boards | Yes |

| Bar Code Reader for Feeders & Packaging | Option |

| MIS & Optimization Functions | Yes |

| Off-line Programming | Option |

| Dispenser Specifications | |

| Dispensing Head | Option 1 Head |

| Dispense Method | Time/Pressure |

| Dot Size | Down to 0.5 mm |

| Placement Speed | 6,000 dph |

| Power Sources | |

| Power Supply | 200-230 VAC |

| Power | 700W |

| Air Supply | 80psi, 4cfm |

| Physical Specifications | |

| Machine Dimensions (Approx. L x W x H) | 950 mm L x 980 mm W x 1448 mm H (37" x 38 1/2" x 57") |

| Weight | 364 lbs (165kg) 900 lbs (408kg) with Stand |

| Service and Support | |

| Remote Diagnostics | Yes - TeamViewer via Internet |

| Warranty (Major Components) | 1 Year - Extended Available |

Smart Feeder Integration for Reliable Assembly

Every MC Series pick and place machine includes fully integrated smart feeder management and control software—built into the system from the ground up to enhance reliability, streamline efficiency, and ensure traceability throughout production. Each smart tape feeder features a DB-9 interface connector that plugs into any MC Series smart feeder base, enabling direct communication between the feeder and the machine’s software. A built-in memory module stores a unique feeder ID and essential component data, such as assigned port, feeder size and type, component value, lot and date codes, starting quantity, index increments, and package type.

To simplify job setup even further, an optional barcode reader can scan the part code on a reel and automatically upload all relevant information into the feeder. This eliminates manual data entry, reduces setup time, and prevents errors. Once connected, the system instantly applies the correct parameters, ensuring the right parts are always placed in the right positions. This seamless hardware-software integration allows MC Series machines to maintain consistently high assembly accuracy and efficiency, run after run.

New Innovative Feeder with Built-In OLED Display – KFTA3D Series

This next-generation smart feeder features an integrated OLED display and internal memory that continuously stores and updates key component information. Operators can instantly view reel quantities, feeder slot locations, part numbers, and part values whether the machine is running or offline. With real-time data visible directly on the feeder, setup becomes faster, more accurate, and less error prone. This added layer of visibility ensures the right components are loaded correctly from the start, preventing costly mistakes before they reach the inspection stage.

An internal battery ensures that stored data remains accessible even when the feeder is disconnected from the machine. Whether you’re tracking part usage during production or verifying setup offline, the system provides a consistent and reliable overview of component consumption. Additionally, these feeders are designed for efficient use of rack space; a 12 mm feeder only occupies a single slot, allowing for higher feeder density and greater flexibility during job setups. By shifting critical data access to the point of use, these smart feeders significantly improve both traceability and productivity in any high-mix SMT environment.

Universal Smart Stick Feeders for Maximum Flexibility

Manncorp’s smart stick feeders offer seamless integration with MC Series pick and place machines and can be positioned directly alongside smart tape feeders for efficient use of feeder rack space. Available in 5, 10, or 20-lane configurations, these feeders provide the flexibility needed for a wide range of component types and production requirements.

Using DB-9 interface connectors, each feeder communicates directly with the system software through the smart feeder base. Built-in memory modules store unique ID numbers that link each lane to its specific feeder position and associated data, including component specifications, belt indexing increments, and precise on/off timing for the vibratory mechanism. This intelligent design ensures accurate, consistent part delivery while simplifying setup and minimizing the risk of operator error.

Flexible Tray and Cut Tape Handling for MC Series Machines

MC Series pick and place machines feature spacious, open work areas designed to accommodate a variety of component presentation methods, including waffle trays and cut tape strips, for maximum flexibility during production.

The TS-1 Waffle Tray Holder occupies approximately 13” x 5.5” (330 mm x 140 mm) of the work area and is designed to securely hold a standard 12.4” x 5.35” (316 mm x 136 mm) JEDEC matrix tray—or up to two cut strip tape holders. Its adjustable design supports a wide range of smaller matrix tray and waffle pack combinations and can easily be modified for custom tray configurations as needed.

For low-quality components or those supplied in short tape lengths, CST Cut Strip Tape holders offer a practical solution. These holders allow operators to present components that are not long enough to be used with standard tape feeders, helping reduce waste and improve efficiency. Standard holders are available for 8 mm, 12 mm, 16 mm, and 24 mm tape widths, with additional sizes available upon request.

Smart Feeder Software: Seamless Setup, Tracking, and Changeover

Included as standard on all MC Series pick and place machines, Manncorp’s advanced smart feeder software simplifies and accelerates production with intelligent features that reduce setup time and eliminate manual data entry. From automatic quantity tracking to feeder position verification, the system ensures accurate, repeatable results across both short runs and high-volume jobs.

One of the key capabilities is automatic component quantity tracking. During production, the software continuously monitors component usage and updates each feeder’s onboard memory with the quantity remaining on the reel. This data is retained even after the feeder is removed. When reloaded—even for a different job—the feeder automatically communicates its remaining part count to the assembly program, allowing production to resume without recalibration or manual input.

Feeder position verification ensures components are being pulled from the correct locations. When optimized feeder positions are used, the machine compares smart feeder IDs with predefined slot data to confirm correct placement. If optimized positions are not used, the system can perform position scanning, identifying each feeder’s location automatically and mapping it to the corresponding pick-up point in the assembly file for fast, error-free changeovers.

To support flexible production environments, quick-change feeder location functionality allows operators to move feeders to new slots or maintain the same layout across consecutive runs without editing the pick and place program manually. For even greater convenience, an optional barcode reader can capture component data such as part value, lot code, date code, and starting quantity directly from packaging—cutting out time-consuming manual entry and reducing the risk of data entry errors.

Smart Tape Feeder Carts for Secure Storage and Off-Line Kitting

Safely transport, store, and organize your Smart Tape Feeders with Manncorp’s durable, dual-tiered Smart Tape Feeder Storage Cart. The FR-ST64 model (pictured) holds up to 64 individual 8 mm Smart Tape Feeders, making it ideal for off-line kitting and streamlined production preparation. Designed for mobility, the cart moves easily from the kitting area to the production line, helping operators stage feeders in advance for faster setup and changeover.

Built with heavy-duty tubular steel construction, the cart holds each feeder securely in place while protecting against bumps and impact during transport. Whether you’re preparing for a high-mix production run or simply looking to keep your feeders organized and damage-free, the FR-ST64 is a reliable, space-saving solution for any SMT operation.

Automatic Index Adjustment to Eliminate Pickup Errors

MC Series pick and place machines feature automatic index adjustment using vision-board alignment. When a new reel is loaded into a feeder, the machine can detect slight offsets in tape pocket position and automatically advance or reverse the feeder to correct it—ensuring accurate component pickup from the start. This is especially valuable when switching reels, as minor misalignments between tapes can lead to placement errors. For reels with looser tolerances, the system can be set to verify alignment and adjust indexing on every pickup, preventing recurring errors and maintaining consistent, reliable performance.

Back

Back